What is a turbine?

A turbine is a machine that plays a key role in transforming fluid or air energy into usable work or electricity.

With a rotor system at its core, a turbine harnesses the rotational energy generated by the fluid to produce a wide range of applications. Here we’ll delve into the intricacies of turbines, their types, and their role in various industries and energy generation.

Understanding turbines and their functionality

Turbines achieve their energy conversion through two primary mechanisms: mechanical gearing and electromagnetic induction. They are primarily employed for generating electricity, but their uses extend to powering mechanical systems.

Mechanical power derived from turbines traces back to ancient Greece. The earliest wind wheels were dependent on gearing and shafts to drive machinery.

This concept of using wind or water as fluid mediums to drive turbines evolved into what we now call windmills and waterwheels. These were instrumental in grinding grain by driving millstones, as well as powering other mechanical processes.

Types of turbines and their applications

Turbines come in different forms, tailored for specific applications and energy sources. These are the prominent types of turbines:

Steam turbines

Steam turbines, widely employed in conventional power plants, generate mechanical energy from burning oil, coal, or even nuclear power. These thermal steam turbines remain one of the most common methods for producing electricity globally. They are renowned for their efficiency and reliability, effectively converting thermal energy into mechanical energy.

Wind turbines

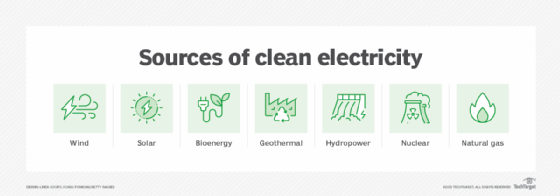

Wind turbines have captured global attention as one of the pillars of green or clean electricity generation strategies. Working on the principles of aerodynamics, wind turbines harness the kinetic energy of wind to generate electrical power. They have gained significant momentum in wind power applications, contributing to the shift toward sustainable and clean energy sources and support for corporate environmental, social and governance (ESG) initiatives.

Gas turbines

Gas turbines provide a versatile and efficient solution for various industrial needs. They use combustible fuels such as natural gas or diesel to generate mechanical energy. The resulting power is used extensively in power plants, aircraft engines, and various industrial applications. Gas turbines are highly regarded for their compact size, quick startup, and ability to adapt to fluctuating loads.

Hydroelectric turbines

Hydroelectric turbines harness the potential energy of flowing water or hydraulics to generate electricity. They play a crucial role in hydroelectric power plants, converting the energy from river dams or tides into electric power. Hydroelectric turbines are celebrated for their renewable nature, sustainable operation, and minimal environmental impact.

Industrial and commercial applications of turbines

Turbines find wide-ranging applications across numerous industries, including the following:

Power generation

Turbines, in collaboration with various power generation technologies, form the backbone of an electricity supply. They drive generators, enabling the conversion of mechanical energy into electricity. Power plants, both conventional and renewable, rely on turbines to generate the enormous amounts of electricity demanded by society.

Aerospace and aviation

The aviation industry heavily relies on turbines to power aircraft engines. Turboprop and turbofan engines, powered by gas turbines, provide the thrust required for aircraft propulsion. These turbine-driven engines offer high performance, fuel efficiency, and reliable operation, making air travel more efficient and safer.

Oil and gas industry

In the oil and gas sector, turbines play a crucial role in powering various operations. Gas compressor stations rely on gas turbines to compress natural gas for transport across pipelines. Refineries and petrochemical plants employ turbines for driving pumps, generators and other essential equipment, ensuring smooth and efficient operations throughout the industry.

The challenges facing turbines

While turbines have revolutionized industries and energy production, they also face several challenges that demand continuous innovation and improvement. Overcoming these hurdles is crucial to their long-term efficiency, reliability and sustainability. Let’s examine the key challenges that turbines encounter and the ongoing efforts to address them.

Efficiency optimization: Maximizing energy conversion

Efficiency is a paramount concern when it comes to turbine operation. Engineers and researchers constantly strive to enhance the aerodynamic design of turbine blades to maximize energy extraction from fluid or air. By improving blade profiles, reducing drag, and minimizing energy losses, turbines can achieve higher conversion efficiencies and generate more power from the same input.

Additionally, advancements in materials science and manufacturing techniques contribute to increased turbine efficiency. Lightweight and robust materials, such as composites and superalloys, allow for higher operating temperatures and better fatigue resistance.

These improvements reduce energy losses and enable turbines to deliver enhanced performance over extended periods.

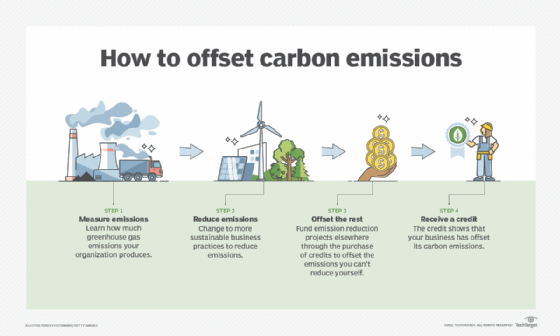

Environmental impact: Mitigating noise, visual and ecological concerns

Turbines, especially wind turbines, have faced criticism due to their environmental impact. Noise pollution and visual aesthetics are a primary concern in wind energy projects, particularly those located in populated areas.

To address this challenge, manufacturers and researchers are developing sophisticated noise reduction technologies and implementing advanced design strategies. Innovations include the optimization of blade shapes and the use of noise-dampening materials to minimize turbine-generated noise levels.

Ecological factors are also considered when deploying turbines in sensitive environments. Proper placement, thorough environmental impact assessments, and collaboration with environmental experts are crucial to ensure minimal disruption to local habitats and wildlife.

The development of bird-friendly designs, such as improved blade visibility and tower lighting practices, is an ongoing focus of research to further mitigate environmental impacts.

Grid integration: Balancing supply and demand

As renewable energy sources, including wind and hydroelectric power, gain prominence, electric grid integration poses a challenge for turbines. Their intermittent nature and fluctuating power output require effective management to maintain a stable and reliable electricity supply.

Balancing supply and demand is essential, especially when the power produced by turbines exceeds the grid’s immediate capacity.

To address this challenge, advanced monitoring and control systems are being developed to optimize turbine operations and ensure seamless integration with the grid. These systems incorporate predictive analytics, energy storage solutions, and demand response mechanisms to effectively regulate power output and support grid stability.

Maintenance and reliability: Maximizing uptime

Turbines require regular maintenance and periodic inspections to ensure optimal performance and longevity. Challenges arise due to their often remote locations, vast numbers, and the complexity of their components. Accessing turbines for maintenance purposes can be challenging, especially in offshore wind farms or remote areas.

To address this, the manufacturers and user organizations are investing in remote monitoring and maintenance technologies, including advanced sensors and predictive analytics. These tools enable early detection of potential failures or performance issues, allowing for timely maintenance and reducing costly downtime.

Improved maintenance practices, such as condition-based monitoring and robotic inspection techniques, ensure that turbines operate efficiently and reliably.

Cost Competitiveness: Achieving affordability

While the costs of turbine technology have been steadily decreasing over the years, achieving cost competitiveness remains an ongoing challenge. Reducing the overall costs associated with turbine manufacturing, installation, maintenance, and decommissioning is crucial to accelerating the adoption of renewable energy sources.

Technological advancements, economies of scale, and streamlined manufacturing processes play a vital role in reducing costs. Additionally, research and development efforts focus on identifying alternative materials, innovative designs, and enhanced manufacturing techniques to drive down expenses without compromising quality and performance.

By overcoming these challenges, turbines can further strengthen their position as indispensable machinery in the quest for a greener and more sustainable future.

The future of turbines

Turbines represent an essential technology in efficient energy conversion and utilization. From power generation to aerospace and beyond, turbines continue to propel numerous industries forward.

As the world explores renewable energy sources and seeks to minimize human environmental footprint, turbines, especially wind and hydroelectric turbines, are gaining prominence. Emerging technologies, such as improved aerodynamics, advanced materials and sophisticated control systems, also strive to maximize energy conversion, optimize performance, and reduce environmental impact.

Check out our sustainability and ESG glossary with 52 terms you need to know. Explore six ways to increase energy efficiency in data centers and four ways to reduce network power consumption. Read about ways to build a green IT culture and lower IT‘s digital carbon footprint. Learn strategies to work toward data center decarbonization, and see how CIOs can drive environmental sustainability.